Sintered PTFE

Cobetter Sintered Microporous PTFE is porous format PTFE plastic. It is molded through high temperature and high pressure molding. This process does not cause melting or changing the major properties of the material itself, but creates a uniform porous structure. Sintered PTFE is composed of pure Polytetrafluoroethylene PTFE material, without any adhesive, and possesses the natural hydrophobicity, outstanding strength, high temperature resistance and high chemical stability of PTFE material itself.

Through the molding process, the structure design of porous sintered PTFE has great resilience and flexibility. Cobetter can design and manufacture PTFE materials into 2D and 3D structure components and support various customized shapes, providing customers in different industries with integrated product solutions from R&D to large-scale production. We can provide sheets, rolls, plates and other customized-specific formats (such as rods, tubes, nibs, etc).

Sintered PTFE filter is naturally hydrophobic, which can prevent the passage of liquid under a certain pressure, while allowing free passage of gas. These can be adjusted and achieved by changing the sintered pore size. We provide sintered PTFE with different pore sizes to meet the actual needs of different applications.

Customized-size Sintered PTFE Frits and customized-thickness Sintered PTFE Membranes are available.

Manufacturing Process

Physical Properties

| Working Temperature | -260 to 260°C |

| Pore Size Available | 0.1 μm ~ 20 μm |

| Porosity (pore volume) Range | 30 - 70% |

Chemical Properties: PTFE vs PE

| Chemicals | PE | PTFE |

| Acids (non oxidizing) | Good | Good |

| Bases | Good | Good |

| Oil | Fair-Good | Good |

| Aromatic solvents | Poor

| Good |

| Non-polar aliphatic solvent | Fair | Good |

| Polar-aprotic solvents | Fair-Good | Good |

| Polar-Protic solvents | Fair-Good | Good |

| Halogenated solvent | Poor | Good |

| Oxidizing agents | Poor | Good |

Geometric Options

- Standard rolls or sheets - Discs - Plates - Tubes | - Rods

- Nibs - Cup shape - Other 3D customized structure |

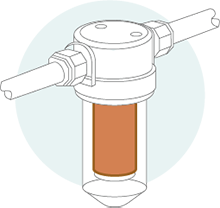

Typical Application 1. Disposable Sintered PTFE filters for Industrial Gas Analysis |

Cobetter provides Industrial customers with disposable hydrophobic sintered PTFE filters for gas analysis and particle filtration, such as gas monitoring equipment. Especially suitable for filtering high temperature gas and corrosive gas.

PTFE filter elements are produced by sintering pure PTFE granules. The maximum temperature resistance can reach 260°C. It is formed at one time and is easy to assemble. It has the characteristics of high flow rate, low pressure drop and long life-term. The filter is naturally hydrophobic, which can block the liquid water produced by the condensation of water vapor in gas. The pure sintered PTFE avoids the adsorption problem of the target gas by the supporting layer in the supporting ePTFE membrane. We provide hydrophobic porous PTFE filter with different filtration accuracy to meet the applications of different particle filtration efficiency requirements.

|  |

Physical Properties

| Working Temperature | -260 to 260℃ |

| Filtration Efficiency | DOP 0.3μm ≥ 99.99% |

| Air Flow Rate | up to 15L/min in air @ 25°C |

Regular Sizes

| Inner Diameter | Height | Filtration Accuracy (μm) |

| 12 mm | 32 mm | 2, 3, 10, 20, 25, 40, 70… |

| 12 mm | 57 mm |

| 15 mm | 30 mm |

| 25 mm | 64 mm |

| 25 mm | 178 mm |

| 38 mm | 58 mm |

Many other standard and custom sizes available.

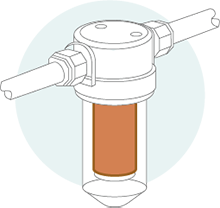

Typical Application 2. Sensor Applications such as Sensor Protection Shell |

| Cobetter sintered PTFE filter is frequently used in the protection of electronic products. Especially suitable for environments with high humidity and corrosive risks. PTFE sintering has a stable IP protection and filtration level. Its hydrophobic and ventilating ability can protect sophisticated electronic components from contamination by moisture, oil, and particulates, and ensure gas flow, balance external pressure, and minimize the risk of component damage. We can provide sheet, ring, tube, cup and other forms to support customer customization. |

Regular Sizes

| Inner Diameter | Outer Diameter | Height | Pore Size |

| 10mm | 12mm | 20mm | 10μm |

Key Measuring Properties

- Water Entry Pressure (WEP)

- Maximum Working Temperature

- Air Permeability (Gurley)

- IP Protection Grade

- Particle Filtration Efficiency

- Moisture Vapor Transmission Rate

Applications

- Temperature and humidity sensor protective cover

- Gas analysis sensor protection cover

- Environmental monitoring sensor protection shell

- Optical sensor

Properties and Benefits

- Dustproof and waterproof

- Anti-corrosion

- Higher strength compared with Expanded PTFE

- High temperature resistance

- Low adsorption: pure PTFE avoids the adsorption of the object to be tested by the support layer

- Enhance sensor performance

- Extend sensor life

- Thin thickness Sintered PTFE Membrane is also applicable.

Structure and Size

- Customize various 2D, 3D shapes, with custom joints available.

Typical Application 3. Gas Diffusion Porous PTFE Filter |

The porous structure of sintered PTFE can diffuse gas uniformly and efficiently. In Medical drug delivery applications such as atomizing inhalation drug therapy, the high-precision pore size characteristics of the PTFE sintered filter element can optimize dosage accuracy and deliver consistent drug dose release, ensure the safe filtration of drug. The use of the sintered filter element also prevents cross-contamination. The filter is compression molded, with variety of structures available, such as tube, cylinder, sheet, etc., as well as customized sizes. Regular applications include oxygen moisture bottles, nasal inhalers, spray pumps, drug delivery reservoirs, etc.

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message